08 Sep Photo Etched Speaker Grilles: A Sound Decision

In the past, speaker grilles were almost exclusively manufactured using thick woven aluminium wire. However, as manufacturing processes have evolved, automotive engineers have shifted towards a less time-consuming and inexpensive process without any loss of quality to the component. Now the go-to solution for the manufacturing of high end speaker grilles is photo etching.

Photo etching, also known as chemical etching or photochemical milling (PCM), is a subtractive manufacturing process that uses ferric chloride as an etching chemical to produce intricate and precise metal components.

What is the photo etching process?

The photo etching process works by, firstly, cutting and cleaning the desired metal. After this, the metal is laminated by a blue UV photoresist, which is then printed with a design from CAD artwork. The metal is then developed, washing away any exposed photoresist from the process, leaving just the metal profile for the etchant chemistry to etch through the pieces.

After the profile has been etched, the photoresist is removed to leave the raw metal parts loose or tabbed as part of a larger fretwork sheet of metal.

Photo etching in the automotive industry

The earliest form of recorded photo etching can be traced back to around 400 BCE. Back then, organic lactic acid and citric acid were used to corrode lead to create ceruse (white lead).

Whilst it is nice to imagine the ancient Greek and Egyptian elites being pulled around in chariots featuring ceruse speaker grilles, it wasn’t until 2009 when the technique was adopted by the automotive industry. Before then, perforated metal grilles dominated the high-end market. Given the rudimentary manufacturing process involved in punching holes through metal, this technique was unsurprisingly limited in the scope of designs that could be crafted. It could also lead to damages in the final component, leaving many parts unsuitable for use in vehicles.

However, this all changed with the introduction of chemical etching into the sector. Modern techniques allow the creation of exceptionally fine detail on an extensive range of metals, including stainless steel.

The benefits of photo-etched speaker grilles

Since the introduction of photo etching, automotive manufacturers have experienced several benefits.

No expensive and time-consuming hard tooling

Photo etching has the unique distinction of not requiring time-consuming and expensive hard tooling. Digital tooling eliminates that process giving everyone the freedom to experiment on designs without expensive set-up or modification charges. The use of digital tools also means products can be turned from prototype to production within a matter of hours.

Burr and stress-free speaker grilles

The fast turnaround in production is also possible because, unlike stamping, photo etching is a burr and stress-free process. The quality of the final component is assured as there’s no damage during the process.

Precision accuracy, unlimited creativity

It’s possible with photo etching for openings and surface engravings to be made to ±0.025mm accuracy. The level of s complexity is almost unlimited, allowing designers to add high-definition logos. There’s also the opportunity to have openings of any size, shape and in any position.

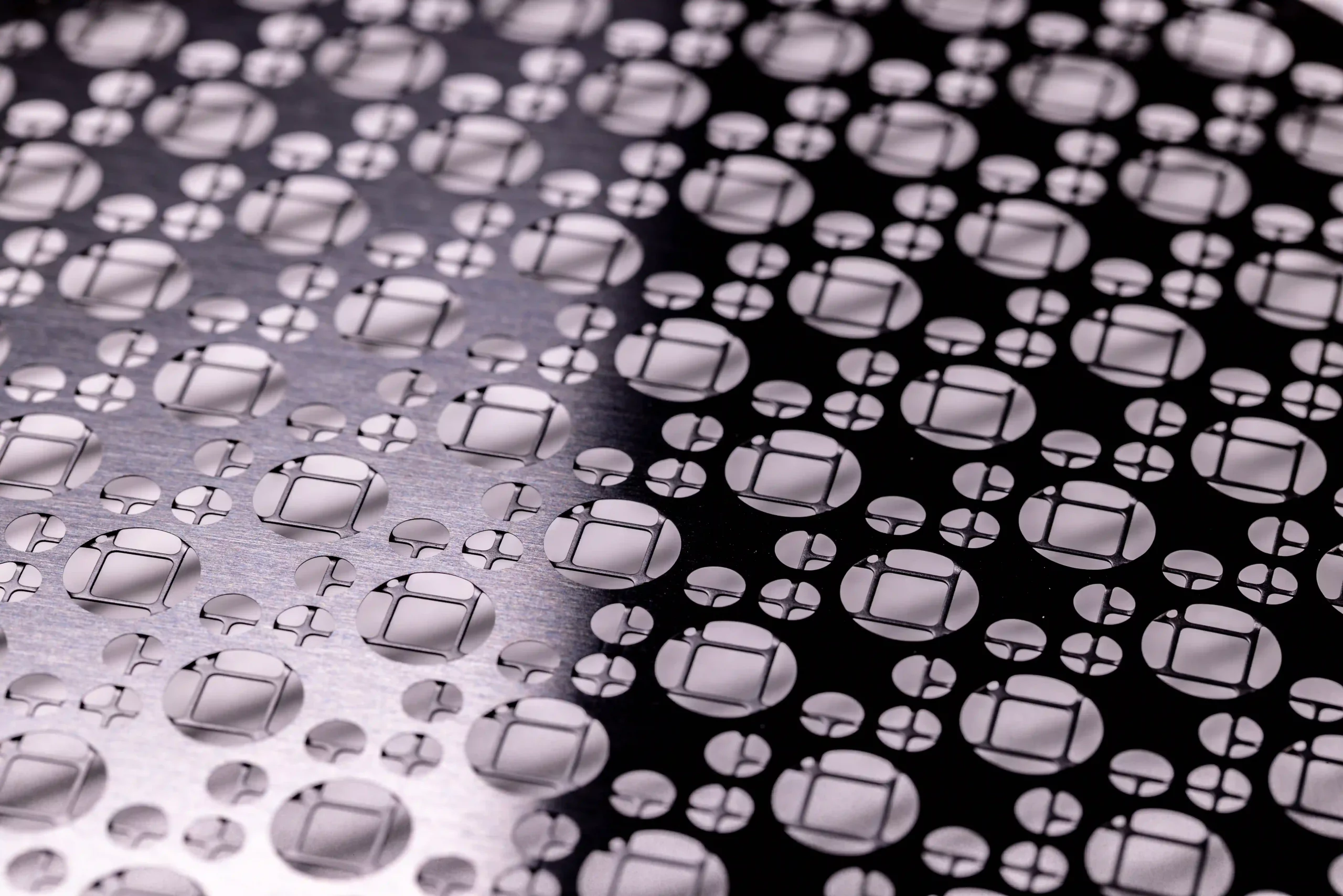

Double-sided etching produces apertures through the material, which aren’t limited to one single-sized, repeated hole shape. Beyond some simple design considerations (the smallest opening that can be achieved is the thickness of the material & land between apertures must be 1.5 x material thickness to maintain structural integrity), there is unlimited design freedom to create truly stand-out speaker grilles, allowing them to become a stand-out decorative feature of any car interior.

Photo etched speaker grilles from Vestatec

By working with Vestatec, we can also use our in-house processes to further enhance the finished photo etched speaker grilles.

With half etching and surface etching, further detailing can be added to the grille. When combined with PVD coating, half-etched surface areas create a nice colour contrast to the main surface. The use of PVD to coat components also allows for decorative features of the substrate surface to be enhanced, whether this be polished, brushed or matte.

Summary

Essentially, the use of photo etching is the best way to maximise the decorative potential of speaker grilles. Whether you want to incorporate images, logos, wording, patterns or other intricate details into your designs, almost unlimited complexity is achievable, all within a single process.

From a performance perspective, photo etching is the only method of manufacturing that produces stress and burr free parts without a secondary process. Moreover, it allows the use of thinner materials to help reduce the weight of the car, whilst providing superior rigidity and higher durability.

For more information about our photo-etched speaker grilles, get in touch with the team today.

Sorry, the comment form is closed at this time.