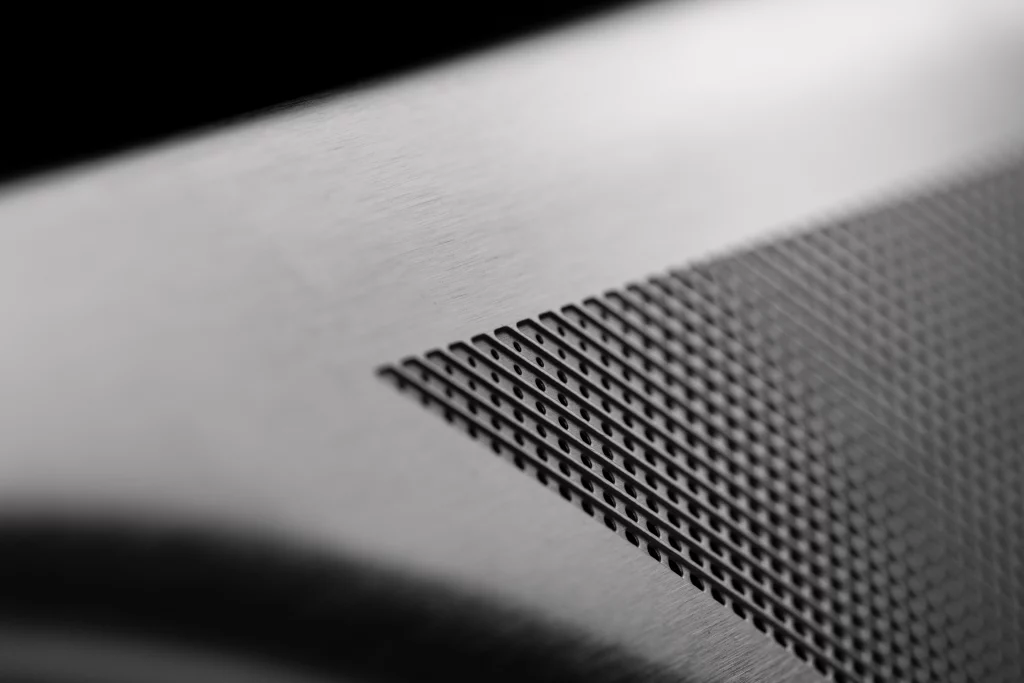

vestatec metal assembly

Our metal assembly processes have been continuously refined over time with the aim of driving efficiency for our clients. Consistency, repeatability, and flexibility are maximised through our commitment to lean manufacturing capabilities.

Once our products have been pressed and coated, we use a combination of automated, robotic and manual assembly lines to finish our components.

Our automated assembly lines allow us to produce high-volume orders by calibrating our machinery to a client’s exact specifications, offering speedy construction. In as little as 30 seconds, your parts can be assembled and ready for final checks.

Our Robot Assembly Cell in action.

We’re driven by detail, which is why at every stage of the process our team conducts rigorous quality checks to ensure the highest level of accuracy. Our skilled team of workers visually inspect each component and rejects products displaying any flaws or blemishes. This ensures consistently high quality in our fulfilled orders.

From interior focal points to discrete integrated parts.

Quick lead times

Depending on the complexity of the component, we can offer fast turnaround on samples and series production.

Flexibility

Our assembly lines can be adapted to meet any requirements, combining automation and robotics with the know-how of our skilled workforce.

Since 1987, Vestatec has been a leading specialist and innovator in the metal forming and assembly of complex and detailed precision components for aesthetic or high-performance applications.

Grounded in the principles of British quality and artistry, our difference is in the detail – in the excellence of engineering, the quality of finish and the development and design of solutions. Using multiple processes and state-of-the-art equipment, we’re able to create components with complex geometries and high-quality detail, enhancing aesthetic appeal, user experience and brand differentiation.

We are driven by detail across all our engineering capabilities.

Customers we proudly work with

We’re ready to show you what’s possible. Get in touch to find out more about our metal assembly capabilities.